Why Have a Building Energy Audit Performed?

There are several reasons having an energy audit done is the right decision for most building owners.

To Reduce Your Operation Expenses, Increase Your Profit

In these days of uncertainty, it is important to keep operating expenses to a minimum. One difference between companies that weather these difficult times and those which do not survive, will be that the survivors will have reduced their unnecessary expenditures before it is too late.

Unnecessary costs include costs for energy you don’t need to use. In the past, many companies have just considered utilities as “a cost of doing business.” By running an inefficient building, you are overpaying your utility for energy. It just doesn’t make any sense.

A good building energy audit will point the way to reduce your energy costs by 10% to 40%. For large organizations, this can be substantial, and could mean the difference between staying afloat and going under.

To Determine Which Are the Best Building Energy Efficiency Measures

There are so many vendors peddling their energy efficient devices which are supposed to save energy–most of them do, but some don’t. Just because a device saves energy does not mean it is a good investment. And even if it is a good investment, there may be better energy efficiency investments available.

For example triple-pane windows that you hear advertised on the radio usually save energy, but for some buildings, they will actually result in an increase in energy usage. It is usually a better investment to replace your incandescent light bulbs with CFLs than it is to change out your windows.

So how do you determine what are the best energy conservation measures for your building? That is what an energy audit is for.

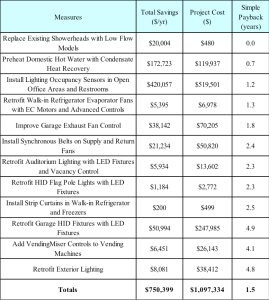

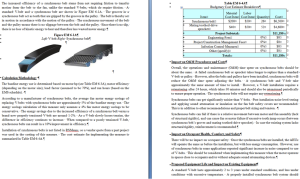

The table below lists energy conservation measures from an audit we recently performed on a large office. In this format our client is able to easily evaluate and prioritize the different energy efficiency opportunities.

(If triple pane windows were on this list, the simple payback would likely have been over 15 years. It may sound good on the radio, but a sober analysis shows that there are better ways to spend your energy efficiency dollar.)

To Increase the Value of Your Building

We understand the argument that if your tenants are paying the utility bills, then there is no reason to invest money in making your building energy efficient. After all, you won’t be reaping any energy savings.

Keep in mind that increasing the energy efficiency of your building will increase in value. If you have a “green” building, your tenants will be happy to pay higher rents to occupy your building.

On average for every dollar spent in energy efficiency improvements, appraised building value increases several times.

What is a Commercial Energy Audit?

The term energy audit appears to refer to two distinct things: An energy audit is the process of having a professional energy auditor assess your building for energy savings opportunities. The term energy audit also is used to refer to the result of the energy assessment process, the energy audit report. We will try to keep these terms separate by referring to the report as an “energy audit report.”

An energy audit report is a carefully thought out plan, which, if followed, will lead you to reduced energy costs. Every building is different, and each contains different opportunities which can reduce energy usage. This is why every different building requires its own unique energy audit.

During the energy audit, an energy auditor will visit your site and interview your facility manager, inspect your lighting, air conditioning, heating and ventilation equipment, controls, refrigeration, air compressors, water consuming equipment, and anything else that is using energy. Depending on the type of audit, the auditor may take measurements of temperatures, pressures, light levels, power draw, and other things.

An energy audit report typically contains a description of the building’s existing energy consuming equipment, an energy balance and most importantly, a presentation of feasible energy conservation measures (ECMs). Each of these measures are developed so that the report includes :

- a description of the existing conditions

- a description of the proposed ECM

- expected annual savings associated with the ECM

- expected cost to implement the ECM

- simple payback and/or other financial measures, such as return on investment or life cycle savings

Some of the ECMs identified in the audit will take decades to pay for themselves, while others will start paying for themselves within months. Once you have the audit in hand, you can make good decisions as to where to invest your energy efficiency money.

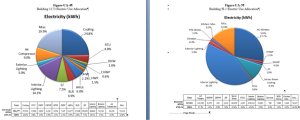

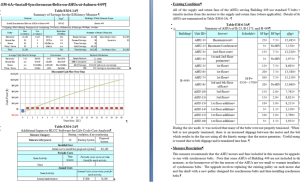

Some of the sections of an ASHRAE Level 2 energy audit are presented below:

Facility Summary: A description of the building and its energy consuming equipment

Energy Balance: A breakout of facility energy usage into end uses.

We investigate and quantify energy savings potential in:

- Lighting systems

- HVAC Systems and Controls

- Compressed Air Systems

- Renewable Energy Applications

- Electric Motors and Drives

- Process Systems

- Steam Systems

- Heat Recovery

- Building Envelope Upgrades

- Switching Utility Providers or Utility Rates

How much money/energy can be saved by getting an energy audit?

When talking about possible energy savings in a facility from performing an energy audit, it’s impossible to make a reasonable estimate without understanding how the building operates and uses energy.

With that said, we’ve seen savings upwards of 40% on some facilities, with the average savings being around 10-20%. If the facility has already had energy audits in the past, and the identified measures were implemented, it’s possible that the facility is already efficient, and in that case, there might be much less energy savings potential. If the facility has been in operation for many years without having had an energy audit, it’s very possible that an energy audit can save you a significant amount of money.

If you want to make an easy estimate, for a building that has not aggressively pursued energy efficiency in the past 10 years, assume 20% savings potential. For a building that has been pursuing energy efficiency in the past 5 years, assume 10% savings potential. These estimates cannot be too far from the truth.

Since it’s extremely difficult to assess how much your facility can save without knowing more about your company, we will gladly provide you with a Free Energy Audit Consultation.

By having this consultation, we can decide whether or not you need an energy audit at all, and if you do, what kind would best suit you and your facility. Here’s an example of energy wasted. This is an over-lit, air conditioned server room- click on the image at right to see the lack of servers in it.

Don’t All Auditors Produce the Same Quality Work?

Sadly, no they do not, nor do energy auditors have the same degree of proficiency at their craft. And what is worse is that most commercial energy audit customers may not be able to tell qualified energy auditors from novices. Energy auditing is a profession, like lawyering. Not all lawyers can produce the same results–the same applies to energy auditors.

The quality of your energy audit report really matters. A poorly done audit can result in you:

- Wasting thousands of dollars in installing the wrong energy conservation measures. Most facilities have a limited budget for energy efficiency. It is best to use that budget on the best energy conservation measures. Poorly done audits often miss these.

- Wasting thousands of dollars installing energy conservation measures that won’t save money, or that will save much less than the audit would lead you to believe.

- Wasting thousands of dollars in wasted energy from not knowing about no-cost/low-cost measures that could have saved you money. These measures often are related to HVAC control, and inexperienced auditors often miss these.

There are more ways a poorly done audit can lead you astray, and these are addressed in detail in our whitepaper Eight Ways in Which a Poor Quality Energy Audit Can Prove Costly to the Building Owner.

If you plan on acting on the recommendations presented in the energy audit report, then be wise when you choose an auditor. Be sure to pick an auditor who:

- is vendor neutral

- is solution neutral (i.e. who won’t be pushing a performance contract or service on you)

- has experience. Be sure to look at resumes, and descriptions of past projects.

For more information on picking the right energy auditor, see our whitepaper How to Avoid Energy Audit Disasters.

Remember, bad advice is worse than no advice.

What is the Difference between and ASHRAE Level 1, Level 2 and Level 3 Energy Audit?

I have talked to many who claimed that they conduct energy audits–they may have thought they did, but they did not conduct energy audits. An energy audit by an electrical contractor will not likely cover all energy consuming equipment. For example, it is likely that they will miss anything building envelope or boiler related, as they will focus only on those items that might generate revenue for their company: namely transformers and lights. These limited scope type of audits only serve to help the contractor, and are a disservice to both the customer and the industry, as the concept “energy audit” loses value in the eyes of the customer.

Because there was so much variance in the industry as to what exactly composed an energy audit, ASHRAE kindly stepped in and defined varying degrees of energy audit rigor. These different levels of audits are now called ASHRAE Level 1, ASHRAE Level 2 and ASHRAE Level 3 audits.

Some buildings don’t require hundreds of hours of engineering time, and a smaller audit will suffice, whereas for other buildings, the additional time and analysis is well worth the investment. A rightly sized energy audit will provide the right balance between energy audit cost and value of the audit.

The ASHRAE Level audits are recommendations. They are not law. You can always pick and choose what they want and don’t want in the audit. What is most important is that you get value for your money. If you spend $10,000 on an ASHRAE Level 2 audit that finds energy savings potential of $5000, then you overpaid for the audit, and probably should have gotten an ASHRAE Level 1 audit.

Preliminary Energy Use Analysis

All three levels of audits require a Preliminary Energy Use Analysis which involves the following:

- a site visit to assess the building and energy consuming equipment

- analysis of the utility bills to determine whether savings can be had by changing the utility rate

- a summary of utility bill data

- calculation of the energy use intensity (EUI)

- benchmarking to compare the site’s energy usage to that of similar sites in the same region

- estimate of the energy and costs saved if the building met an energy use intensity target

ASHRAE Level 1: Walk-through

The ASHRAE Level 1 audit is a walk-through audit that will identify energy efficiency measures (EEMs) while limiting the necessary engineering time and costs to produce the report. The estimated savings and costs associated with each measure are of rough order magnitude. The brief report focuses on low-cost and no-cost measures, although capital measures are identified when found. The report also includes a summary of utility data, the estimation of savings associated with a rate change, the calculation of the energy use index, benchmarking, and targeting.

A small building will use very little energy, and will likely contain very little energy savings potential. For these small buildings, an ASHRAE Level 1 audit should suffice. Conducting more advanced audits on these small buildings may not be the most feasible option.

We often perform ASHRAE Level 1 audits for clients who are seeking LEED-EB status. ASHRAE Level 1 audits are required as a prerequisite to attain LEED-EB status.

ASHRAE Level 2: Energy Survey and Analysis

The ASHRAE Level 2 audit is more detailed and requires proficiency and thought to create a quality audit report. The Level 2 audit includes a complete description of the facility, including an equipment inventory, an energy balance, detailed energy savings and costs associated with each low-cost and not-cost measure, financial analysis of each recommended measure, identification and rough estimates of capital project costs and savings, and a recommended measurement and verification plan for each recommended measure.

The Level 2 audit is the most likely type of energy audit for larger buildings. The Level 2 audit balances the need for engineering rigor with the need to keep energy audit cost effective. The additional accuracy afforded by the Level 3 audit may not be worth the additional cost.

We often perform ASHRAE Level 2 audits for clients who are seeking LEED-EB status. ASHRAE Level 2 audits are worth 2 points (LEED-EB Credit 2.1, Option B) and are sometimes selected by our clients as it is less expensive than Retro-Commissioning (LEED-EB Credit 2.1, Option A).

ASHRAE Level 3: Detailed Survey and Analysis

ASHRAE Level 3 audits are designed to provide additional engineering rigor for more expensive capital projects where risk is less tolerated. In these audits, trend logs and data loggers are used to better understand how the buildings react to changes in ambient conditions and occupancy. Calculations for HVAC measures are done with hourly simulations. Detailed costing estimates are provided, as are life cycle cost assessments. Typically a scope of work and schematics are provided with the audit so that the contractors installing the measures understand exactly what is to be installed. The reports contain more detailed descriptions of the measures.

Level 3 audits are sometimes called Investment Grade Audits (or IGAs). These audits are typically done as part of a performance contract.

What is Retro-Commissioning?

Background: The Unrealized Promise of Building Automation Systems

In the 1980s and 1990s, DDC energy management systems (EMS) were being installed in large buildings throughout the country with claims that they would reduce energy usage. That turned out to be a false claim. An EMS saves energy no better than a hammer builds a house. The EMS is a tool that can be used for good or ill, just as a hammer can be used to build or destroy. With an EMS, an unsophisticated building operator, through use of overrides and poorly chosen setpoints, can waste much more energy than he would have in the past.

For most building operators, the main focus of day-to-day activities is to avoid hot and cold calls. Energy efficiency falls far down the list of concerns. Often this emphasis on avoiding complaints leads to overrides of control settings which may waste significant amounts of energy.

There are other causes that lead to EMS systems not saving energy. Many EMS installers don’t understand energy conservation either. They understand how to install EMS systems, and make them work. However, due to ignorance, poor contract scope, not enough hours budgeted to the job, or value engineering, many energy efficiency strategies are just not programmed into the EMS, which might otherwise have reduced energy usage.

Introducing Retro-Commissioning: The Solution to Underperforming Building Automation Systems

In the 2000s and 2010s Retro-commissioning (RCx) has come along as a popular means to reduce energy usage. Now, all the energy that was supposed to be saved when the EMS was installed, can now be saved because RCx can optimize the EMS, implement missing energy efficient strategies, and reduce energy waste.

According to some authoritative sources, RCx is supposed to get the building back working as it had been originally designed. However, as many in the energy efficiency business know, the original design is often not energy efficient, as it is often the work of architects, whose main focus and area of expertise has not been energy efficiency. A better definition of RCx is to take the building and its controls as they currently are, and to optimize the controls to make the building as energy efficient as is economically feasible, while still maintaining occupant comfort. This optimization is usually done through a combination of repairing control devices (such as economizer dampers), replacing broken components (such as leaky valves, broken VFDs, or faulty sensors), and reprogramming control sequences so that they reduce energy usage.

Whereas energy audits often focus on replacing inefficient equipment with more efficient equipment, RCx focuses on optimizing the control of this equipment.

Typical RCx measures include:

- Replacing temperature and pressure sensors,

- Repairing economizers,

- Scheduling HVAC systems,

- Implementing heating and cooling lockouts,

- Implementing temperature and pressure resets,

- and many more.

RCx studies are more detailed than energy audits. While an energy audit typically involves one visit to a facility, and recommendations are made based on one view of a moving target, RCx employs functional testing, trend logging, and/or data logging to get a better, more in depth, understanding of how the hvac equipment responds to varying conditions. A good RCx study will capture an understanding of how the building operates during the entire year. An RCx study will identify inefficiencies that cannot be found during an energy audit, and RCx will determine the root cause of the problem, so that specific recommendations can be made. Finally, once the recommendations have been made, and the measures have been implemented, RCx often includes a measurement and verification phase, to quantify the savings the measures are actually providing.

RCx is expensive relative to audits, however, the results are usually quite favorable. The building owner can spend the thousands on new equipment, which may or may not work as advertised, or commission an RCx study which not only provides a good return on investment, but also measures and verifies that the savings have actually occurred.

What is the Difference Between Energy Audits and Retro-Commissioning?

An ASHRAE Level 1 or Level 2 energy audit is like a snap shot of a building, whereas retro-commissioning (RCx) is more like a video of the building. If you have an energy audit performed in the summer, the auditor should be able to identify air conditioning problems, but may not be able to identify heating problems, as the heating equipment may not have been running in the summer.

RCx is more focused on how the equipment operates and how the equipment responds to changes in ambient conditions or occupancy. Trend logs and/or data loggers are used to record temperatures, pressures, power, etc. hourly or in 15 minute intervals. This data is then analyzed to identify problems in how the equipment is working. RCx also typically involves functional testing, which is a systematic way of testing how the equipment responds to changes in ambient temperature, occupancy or schedule. Functional testing might answer questions like: what temperature chilled water is being provided when the outside air temperature is 30°F, 40°F, etc. The inputs to the controls are overridden or simulated in order to document the system’s response.

An energy audit focuses on measures that if implemented, will save energy. Many of these measures involve purchasing and installing new capital equipment, such as new chillers, pumps or boilers. RCx focuses on how the existing equipment is controlled. RCx measures are mostly repairing, recalibrating and reprogramming controls and control devices such as temperature sensors and damper actuators. RCx measures are typically inexpensive to implement and typically offer simple paybacks of two years or less.

An RCx study is typically more expensive than an energy audit, however, when you combine the cost of the RCx study with the cost to implement the measures identified in the report, you will find that RCx is typically less expensive than energy audits, as energy audit measures often have longer paybacks.